本机为全功能弯刀机,软件系统具有自己的CAD重绘功能,选择和修改图形方便快捷。

进料机构采用三点单线设计,实现进退刀的平稳运行。

刀片位移防卡刀设计,当刀具因某种原因卡住时自动停止进给。

如果模具严重磨损且无法穿透,推进电机将自动反转并等待加工终止。

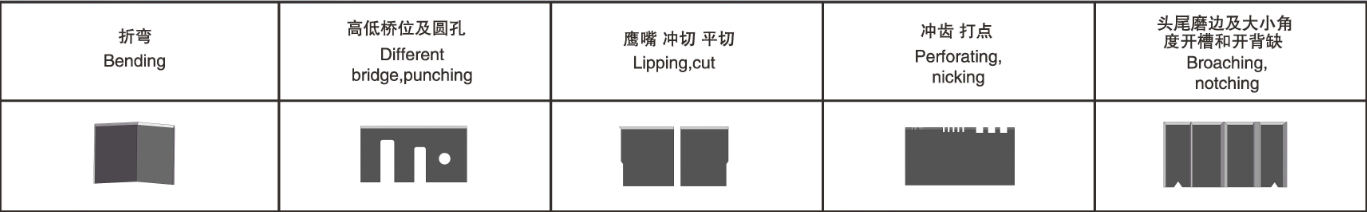

自动识别鹰嘴和易货自动加长,整机采用5刀头设计,实现双组开槽。

点根据标记的线长自动识别点宽度,自动识别槽的大小和角度。

| 技术参数 | |

| 无厚度范围: | 0.45mm-0.71mm |

| 无高度范围: | 8mm-30mm |

| 双锯片点锯片高度: | 23.8毫米-30毫米 |

| 双锯片点锯片厚度 | 0.53mm-1.05mm |

| 支持磨头和磨尾斜边范围: | 软件设置任意磨削斜边的起始角度 |

| 最大无槽弯曲角度: | 100 ° |

| 头尾最小弯曲尺寸: | 1.5mm至2mm,取决于刀片厚度 |

| U型最小槽间距: | 叶片厚度1mm或以上 |

| U形最小弯曲间距: | 间距5mm(尺寸以上5mm软件自动释放后角弯曲) |

| 头部和尾部的最小剪切尺寸: | 1毫米 |

| 切割模式: | 多功能剪刀,可剪去头尾废料 它可以自动判断两者的剪切情况 一次剪切,当剪切水平不足时拉回剪切 |

| 一次性剪切刀片范围: | 高度:8mm-35mm(40个定制) 厚度:0.53毫米至1.05毫米 |

| 进给精度: | ±0.05毫米 |

| 弯曲平整度: | ±0.5毫米 |

| 支撑弯曲刀片高度: | 8毫米-32毫米(40个定制) |

| 支持弯曲刀片厚度: | 0.45毫米-1.07毫米 |

| 桥梁宽度尺寸: | 宽度可选:3mm至6mm |

| 鹰嘴大小: | 宽度可选:3mm至6mm 桥高手动调节杆调整 软件根据桥梁宽度支持自动加宽 鹰嘴尺寸手动调节杆调节 |

| 最佳图形格式: | dxf.ai.dwg |

| 设备环境: | 通风,40度以下干燥 |

| 设备压力要求: | 4Kg/cm2压力,10mm喉部直径 |

| 电源要求: | AC:220V 50Hz必须正确接地 |

| 机器功率: | 2.9千瓦 |

| 包括木箱在内的整机重量: | 机器790KG起重工具托盘251KG |

| 设备外形、占地面积和木箱尺寸: | 260cm×75cm×165cm(占地面积) 195cmX135cmX80cm(设备木箱尺寸) 75cmX80cmX116cm(升降机仓库木箱尺寸) |

| Machete机器系统支持语言: | 简体中文和英文 |

| 软件计算机操作平台: | Windows7或更高版本 |

整机配备6轴一体化高速控制系统,整机有6套伺服驱动,以太网传输控制,快速稳定。

进料采用双夹刀,前后齿台湾TBI螺钉,配上下两条银导轨,弯曲采用国内先进品牌高精度伺服驱动,配日本新宝高精度减速器,高效稳定。

气动部分采用日本SMC气缸,台湾原装亚德克电磁阀。

台湾系列传感器。组合动力采用精制涡轮电机和节能电机,干燥声音低,节能。